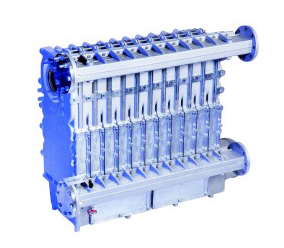

Modular heat exchange technology

Modular heat exchange technology

Full pre-coagulation condensation technology

Full pre-coagulation condensation technology

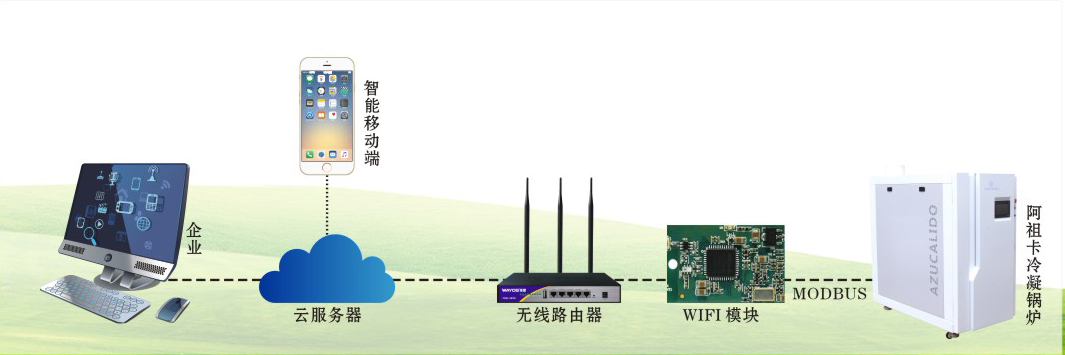

Cloud technology

Cloud technology The original cloud technology control system of SIEMENS in Germany is selected to realize on-site, remote and real-time monitoring and operation of boilers, which is convenient and fast, and realize unattended working mode for boilers.

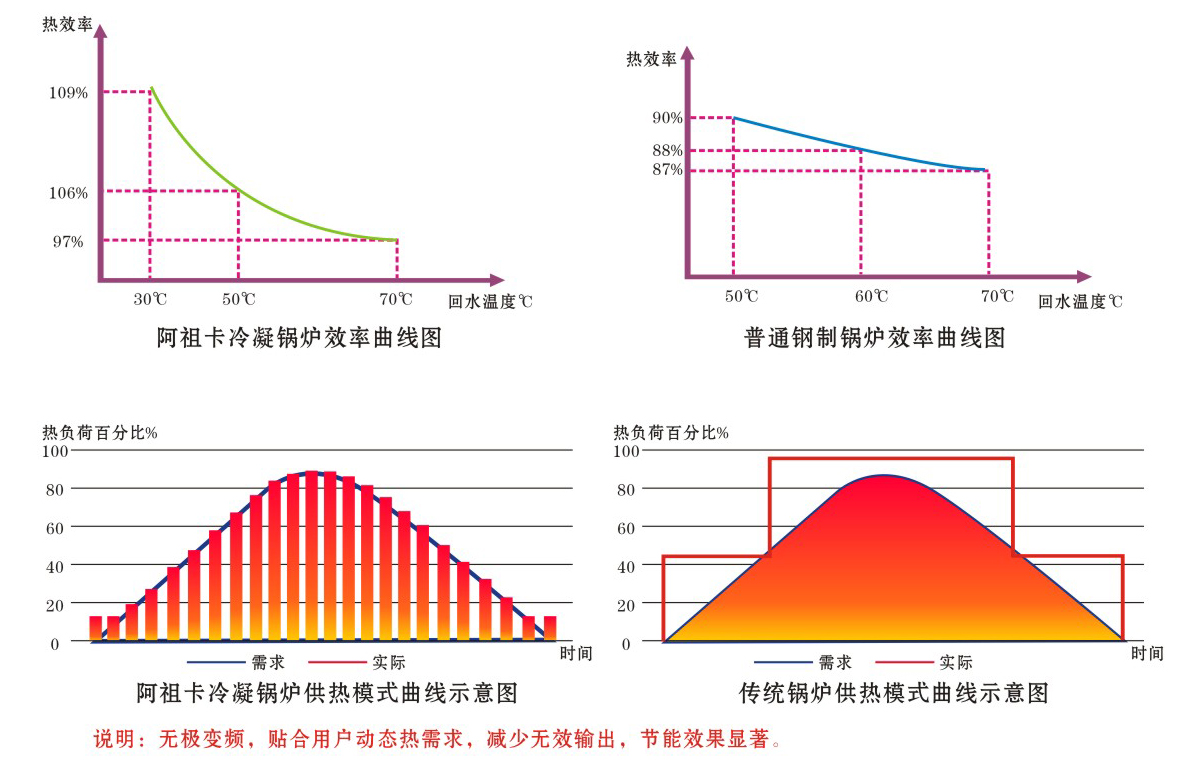

Stepless Frequency Conversion Regulating Technology

Stepless Frequency Conversion Regulating Technology

Safety Monitoring and Protection Technology

Safety Monitoring and Protection Technology  Multiple Intelligent Control Mode Technology

Multiple Intelligent Control Mode Technology Bring customers a new experience accessible, comfortable, energy-saving and portable!

Boiler Design Science

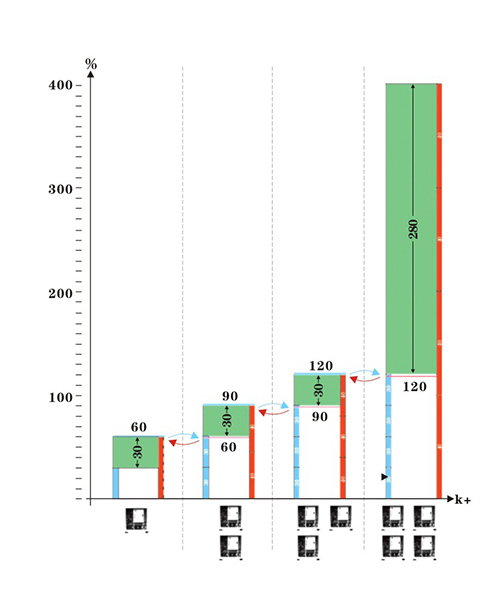

Boiler Design Science  Group Control Intermodal Transport Technology with High Regulating Ratio

Group Control Intermodal Transport Technology with High Regulating Ratio